BIOLOGICAL FILTERS FOR AQUACULTURE

What are

Biological filters?

Biological filters are devices to culture

microorganisms that will perform a given task for us. Different types of organisms will perform

different tasks. Part of the art of designing

and using biofilters is to create an environment that will promote the growth

of the organisms that are needed.

Why do we need

biological filters for aquaculture?

We use biofilters to help maintain water

quality in recirculating or closed loop systems. Biofilters are also used to improve water

quality before water is discharged from a facility. There are many different

methods of maintaining good water quality and biofiltration is only one

component of the total picture. It is

however, a very important and essential component especially for recirculating

aquaculture or aquarium systems.

How will

biofilters help us?

Depending on design and application,

biofilters have the ability to accomplish the following functions. The first three functions are performed by

biological means and the last four are done by physical processes that do not

depend on living organisms.

1. Remove

ammonia

2. Remove

nitrites

3. Remove

dissolved organic solids

4. Add

oxygen

5. Remove

carbon dioxide

6. Remove

excess nitrogen and other dissolved gasses

7. Remove

suspended solids

In general, there are two types of aerobic

microorganisms that colonize biofilters for aquaculture. Heterotrophic bacteria utilize the dissolved

carbonaceous material as their food source.

Chemotrophic bacteria such as Nitrosomonos sp.

bacteria utilize ammonia as a food source and produce nitrite as a waste

product. Chemotrophic bacteria such as Nitrospira sp.

utilize nitrite as a food source and produce nitrates as a waste product. Nitrosomonos and Nitrospira will both grow and colonize the biofilter as

long as there is a food source available.

Unfortunately, both of these types of bacteria are relatively slow

growing. Heterotrophic bacteria grow

about 5 times faster and will out compete the other two types for space if food

is available. Since most aquaculture

biofiltration systems are designed for the purpose of converting and removing

ammonia from the water this presents a problem.

There are three ways to deal with this

problem. The first is to remove most of

the carbonaceous BOD (biological oxygen demand) before the water enters the

biofilter. The second method is to

provide sufficient extra capacity (surface area) in the biofilter to allow all

of the various bacteria to grow. Another

method is to have a very long plug flow path through the biofilter. This allows different zones of bacteria to

establish themselves in different parts of the biofilter.

There are 4 main types of aerobic

biological filters and several subcategories of each. Here is a listing of the major types.

I. Recirculated

Suspended Solids (Activated

sludge and biofloc systems)

II. Aquatic

Plant Filters

A. Unicellular (Microscopic)

B. Multicellular (Macroscopic)

III. Fluidized

Bed Filters

A. Sand Filters

B. Bead Filters

IV. Fixed

film

A. Rotating Biological Contactors (RBC)

B. Trickling Filters

C. Submerged Filters (with or without

aeration)

1. Up flow

2. Down flow

3. Horizontal flow

4. Moving Bed

Anaerobic filters can also be defined as

biofilters but they are never the main biofilter used for maintaining water

quality in the culture system. There are

two main reasons why they are not suitable.

The number one reason is that they are not capable of effectively

cleaning the water to the level required.

The other reason is that they operate too slowly. Anaerobic filters are sometimes used in

aquaculture for conversion of nitrates into N2.

However, this is a difficult process to control and it is generally less

expensive to remove nitrates by discharging a small amount of water from the

system. The water removed with the

solids is usually sufficient to remove the nitrates as well.

Anaerobic biofilters are best suited for

processing high strength waste. The

sludge produced by the physical filter system is an example of a high strength

waste. Processing plant wastes are

another candidate for anaerobic digestion.

In an integrated production/processing plant these two streams could be

combined. The best feature of anaerobic

systems is the production of methane.

There are specially designed engines that can burn this gas to produce

electricity. Using the gas to heat water

is another obvious possibility. However, the capital cost of these systems

generally limits their use to large operations.

General Water Quality Maintenance Principles

Not all aquaculture applications have the

same requirements for biofiltration. Not

only do crops vary in their requirements but different farmers may grow the

same crop under different conditions. The biofilter is only one of several

components of the system used to maintain water quality. The functions that the biofilter must perform

are determined by the presence and effectiveness of other components. Here are some other components and their

effects on the system.

Aeration or

oxygenating systems

If the fish don't have oxygen you are out

of business no matter what else you do.

Aeration is always the first step when increasing carrying capacity over

an open, lightly loaded system.

Mechanical surface aerators, subsurface air bubblers and pure oxygen

injection is the typical progression in terms of technology and

complexity. All aerobic biofilters

require oxygen to operate. If the

biofilter does not provide its own oxygen, it will be limited to the oxygen

carried in with the water.

Particulate

Filters

Once sufficient oxygen is provided, the

next easiest way to improve water quality is to remove suspended solids. This

is a more difficult task since particles come in all shapes, sizes and

densities. Suspended solids consist primarily of uneaten food and feces which

are slightly denser than water. Large particles, above 100 microns, will settle

out quite easily. Particles above 50

microns can be filtered out with a screen.

Particles below 10 microns are difficult to filter and are generally

removed by some other means.

There are many different types of

particulate filters that can remove suspended solids. They generally fall into three broad

categories. The first type are settling

basins, tube settlers, plate settlers, swirl separators and similar systems

that allow the particles to drop out of the flowing stream by gravity. They are relatively simple devices and they

work well on large particles. Settling

systems generally have very low pump head requirements.

The second type are sand filters, sock

filters, drum filters, disk filters, belt filters and similar systems that

mechanically remove the particles from a flowing stream. These types of systems "screen" the

particles. The size of particle removed

is dependent on the size of the screen or sieve. Pump head requirements can vary from low to

very high. Some biofilters such as bead

filters claim to do both particulate filtration and biological filtration.

The third type of particulate filter is

air floatation or fractionation. These

are commonly known as protein skimmers.

In this device, air is bubbled into a column and the fine particles

become attached to the surface of bubbles. The resulting froth or foam is

collected and removed from the system.

These devices require a certain amount of surfactant type compounds in

the water in order to work properly.

Generally speaking, they work better in salt water than fresh water

systems.

Although they are not typically designed

for solids removal, some submerged biofilters will tend to collect fine

particles due to the sticky nature of biofilms.

This can be both a benefit and a maintenance problem. If the biofilter is not designed for easy

cleaning, solids collection can represent a maintenance headache.

Removal of suspended solids is important

since suspended solids comprise the majority of the BOD (Biological Oxygen

Demand). The BOD not removed by the

particulate filtration system must be removed by the biofilter before effective

ammonia removal will occur. Thus the

size of the biofilter is influenced by the effectiveness of the particulate

filtration system.

The way that solids are removed is also

important. The best systems remove

solids quickly without degrading them in any way. If the solid particles are broken or reduced

in size, it makes it easier for nutrients to dissolve into the water. These nutrients must then be removed by

another part of the water treatment system or flushed out by water

exchange. Time is also important because

the longer solids are held in the system, the more degradation will occur. Floating bead filters are particularly bad in

this regard since they hold the solids for long periods of time before backflushing.

Foam

Fractionators

Foam fractionators are very useful but

sometimes optional pieces of equipment.

They are good at removing small particles (under 10 microns) and surface

active compounds. They are sometimes

referred to as protein skimmers. Since

proteins are nitrogenous compounds that degrade into ammonia, foam

fractionators can reduce the load on the biofilters. They are definitely useful in systems where

water clarity is important. Foam

fractionators also add oxygen to the water as a secondary benefit. Unfortunately, foam fractionators do not

always work well in fresh water.

Ozone

Ozone is a powerful oxidizer and sterilant. It is

potentially harmful to fish, humans and most living organisms. It is definitely harmful to biofilters. It is used to improve water clarity and

reduce disease transmission. Ozone should never be used directly before a

biofilter. If ozone is used upstream of

a biofilter, there should be sufficient retention time after the injection point

to insure that no ozone residual enters the biofilter.

UV light

Certain wavelengths of UV (Ultraviolet)

light can be used as a sterilant. UV light is often used with ozone. UV light and ozone are complimentary and

synergistic.

Carbon dioxide

strippers

Build up of CO2 can be a serious problem

in a heavily loaded, intensive recirculating system using pure oxygen. The choice of biofilter has a direct

influence on the degree to which CO2 is a problem. In general, any biofilter other than a

trickling filter or RBC will have a CO2 problem when pure oxygen is used rather

than compressed air for aeration.

Building a CO2 stripper is not a difficult task but it must be included

in the overall design of the system.

In order to remove carbon dioxide, there

must be a large interfacial area between air and water. The interfacial area can be increased through

the use of subsurface aeration, mechanical surface aerators, spray systems or

packed columns. Subsurface aeration is

not very efficient and mechanical surface aerators are difficult to use in an

intensive recirculating systems. Spray

systems can be big energy users and they are not very efficient either. The best choice for intensive and space

limited systems is the packed column.

Packed columns can be either cross flow or counter flow systems. Packed columns for CO2 stripping require fans

to either force (push) air in or induce (pull) air through the packing.

Characteristics of the "Ideal" Biofilter

Before we examine each type of biofilter,

it would be useful to define the characteristics of the ideal biofilter. The following characteristics can be

considered a checklist that we can use to rate each of the different

types. In some cases, different features

may be mutually exclusive but we can use the ideal characteristics as a

yardstick or goal. In practice it may be necessary to trade off one feature for

another but it doesn't hurt to know what the ideal should look like. The following list contains most of the pertinent

features of a good biofilter.

1. Small

footprint - The biofilter should occupy as little space as possible. It is common to have culture tanks and the

biofilters under cover for protection and temperature control. Space allocated for biofilters takes away

area that could be used for culture tanks.

2. Inert

materials of construction - All materials used in the biofilters should be

non-corrodible, UV resistant, resistant to rot or decay and generally

impervious to chemical attack. In

general, marine grade construction materials are required for reasonable

working lifetimes.

3. Low

capital cost - The biofilter must be inexpensive to purchase or build and cheap

to transport to the farm location.

4. Good

mechanical strength - The biofilter and its components must be tough enough to

withstand the normal wear and tear of an industrial/agricultural environment.

5. Low

energy consumption - The energy cost (usually electricity) to operate the

biofilters should be as low as possible.

The largest energy users are the pumps to move water and compressors to

move air.

6. Low

maintenance requirements - The biofilters should be self cleaning with little

or no care required for the normal life of the crop.

7. Portability

- The biofilters should be easily movable to facilitate changes in operation of

the facility.

8. Reliability

- Ideally the biofilters should have no moving parts that could fail at an

inopportune time. If the biofilters does

have moving parts, they should be rugged and designed for a continuous

operating life of several years.

9. Monitorabilty - It should be easy to observe the operation

of the biofilter to insure that it is operating correctly.

10. Controllability

- It should be easy to change operating variables to assure optimum

performance.

11. Turndown

ratio - The biofilters should be able to work under a wide range of water flow

rates and nutrient loading levels.

12. Safety

- The biofilters should not have any inherent dangers to either the crop or the

owner/operator.

13. Utility

- The biofilters should accomplish all of the goals set forth in beginning of

this paper i.e. removal of ammonia, carbon dioxide, BOD, suspended solids etc.

14. Scalable

- A small system should work the same way as a large system. The performance per unit volume should be

constant regardless of the size of the system.

Now that the characteristics of the

"ideal" biofiltration packing have been established, it makes sense

to compare the existing medias to that standard.

Characteristics of Real Biofilters

Activated Sludge

Systems

Activated sludge systems are not common in

aquaculture systems. Activated sludge systems are good at removing carbonaceous

BOD in systems with high nutrient loadings.

They are commonly used in domestic waste water treatment systems.

Activated sludge systems are typically expensive to operate and do not provide

the effluent water quality necessary for aquaculture.

Aquatic Plant

Systems

Plants are not normally used for the

primary biofilter in aquaculture systems.

They do however provide a very good sink for the nitrates produced by a

well functioning biofiltration system.

The marriage of recirculating aquaculture systems and hydroponics is

known as aquaponics.

Aquaponics use the feed resources efficiently

and effectively. In addition to the

valuable plants grown in aquaponic systems, they

minimize the amount of waste that must be disposed of in the environment. Removal of nitrates and phosphorus from waste

water is a big benefit.

Unicellular plants (algae, diatoms etc.)

are sometimes allowed to grow in the culture tanks. Some species such as tilapia are tolerant of

poor water quality and can use the algae as food. Systems operated this way are sometimes

called "green water" or biofloc systems to

distinguish them from the clear water systems that many species require. Green water systems can be a very cost

effective way to culture certain species but they are not recommended for

beginners to aquaculture. Management of

these systems requires some experience and specific knowledge.

Fluidized bed

sand filters

Regular sand filters such as the type used

for swimming pool filters or potable water filters are virtually worthless as

biofilters for aquaculture. The biofilm

quickly fills the spaces between the grains of sand and the pressure drop

across the filter rises rapidly.

Frequent back flushing is required and the active biological film is

removed each time. In contrast,

fluidized bed sand filters have been successfully used for aquaculture

applications. A sand filter becomes

fluidized when the velocity of the water flowing up through the bed is

sufficient to raise the grains of sand up and separate each grain from its

neighbors. In hydraulic terms, the drag

on each particle is sufficient to overcome the weight of the particle and the

particle is suspended in the stream of water.

The velocity required to fluidize the particle is a function of the

shape, size and density of the particle.

Fluidized bed sand filters have several very

good advantages. They pack more

biologically active surface area into a given volume than any other type of

biofilter. In addition, the best shape

for a fluidized bed sand filters is a tall column. Thus they have a small foot print for a given

capacity. They are self cleaning and

relatively tolerant of different nutrient loadings.

There are also several disadvantages and

potential problem areas with fluidized bed sand filters. The fluidized bed sand filter has a

relatively high energy requirement because of the high pressure drop necessary

to fluidize the sand. The other main

problem with sand filters is that the pressure required to fluidize the bed

varies depending on the amount of biofilm on the sand particle. As the biofilm builds on the sand particle

the size of the particle increases while the density of the particle

decreases. This means that the depth of

the bed will tend to increase as the bed ages.

It also means that the bed depth will fluctuate as the loading on the

bed varies. In order to prevent blowing

the sand out of the tank, the tank must be oversized or the flow of water needs

to be regulated.

Another potential problem is the

uniformity of the water flow. In order

to completely fluidize the bed, the water needs to be evenly distributed across

the whole bed. Two things can happen if

the flow is not uniform. One possibility

is that the water will channel and short circuit though the bed. This means

that the treatment capacity will plummet.

Another possibility is that the short circuit will happen near the wall

of the vessel and the abrasive sand will eat a hole through the wall of the

vessel.

Fluidized bed sand filters are limited to

the oxygen carried in with the water.

This means that the water entering the filter should have a high level

of oxygen in order to insure a good level of treatment.

Bead filters

Bead filters are a relatively new type of

biofilter. They are advertised as the

complete solution to water quality for recirculating systems. They consist of a

closed vessel partially filled with small beads of plastic. Usually the vessel is filled with water and

the beads float at the top of the vessel.

Water flows up through the bed of beads.

The beads are small enough to trap most large suspended solids. In addition, the surface of the beads

supports the growth of a biofilm. The

small size of the beads means that they have a relatively large surface area

per unit volume. The larger systems

incorporate a mechanical stirring device such as a propeller on a shaft. Periodically the water flow is shut off and

the bed of beads is agitated to dislodge the suspended solids. The solids are allowed to settle into the

bottom of the vessel and then drained off.

This ability to remove suspended solids and act as a biological filter

is advertized as the main advantage to bead filters.

The difficulty in successfully operating

bead filters lies in striking a balance between the competing functions. Too frequent washing to remove solids

dislodges the biofilm and disrupts the nitrification process. If the beads are not washed enough however,

the solids start to plug the bed. The

other potential problem is the presence of large amounts of carbonaceous solids

which tends to encourage the growth of heterotrophic bacteria at the expense of

the autotrophic bacteria that work on the ammonia and nitrites.

Another drawback to bead filters is their

relatively high energy consumption due to their high pressure drop. Also, the water flow and pressure drop are

not constant. As the bed of beads

becomes loaded with solids, the pressure drop rises and the water flow

decreases. This leads to cyclic rather

than constant performance.

Since bead filters are not aerated, they

are limited to the oxygen carried in with the water. In general this is not a problem since

retention times are low. Bead filter

systems are probably suitable for small, lightly loaded systems where labor

costs are low. At this time they are not

available for large systems except as multiple units.

RBC (Rotating

Biological Contactors)

Like much of the equipment used in

aquaculture, RBC's were first used in domestic sewage treatment

applications. There are several

different types available for aquaculture.

A typical design consists of plates or disks that are attached to a

horizontal shaft. The shaft is located

at the surface of the water and it is turned at a very slow speed (1-5

rpm). The disks are half submerged in

the water at all times. As they rotate,

the biofilm attached to the surface of the disk is alternately exposed to air

and then submerged in the water. The

original designs used an electric motor to turn the shaft. There is a new design specifically for

aquaculture that uses compressed air or pumped water to drive a paddle wheel in

the center of the cylinder. These RBC's

float in the water and do not require bearings or elaborate mechanical

supports.

RBC's have many advantages. They offer

excellent treatment efficiencies. They

require very little energy to operate and can be located in the culture tank to

save space if necessary. They do not

require additional oxygen and are not limited to oxygen contained in the

incoming water. They can remove

dissolved BOD or ammonia depending on nutrient levels. They are biologically robust and handle shock

loads well. It is easy to observe their

operation and visually monitor the biofilm.

They only have one major drawback besides cost and that relates to

reliability. If there is a power failure

or the cylinder stops turning for any reason, the biofilm exposed to the air

can dry out. When this happens, the

cylinder will be unbalanced and can become difficult to turn.

Trickling

Filters

Trickling filters are one of the oldest

types of biological filters. Trickling

filters filled with rock or coal were built in the late 1800's for sewage

treatment. Trickling filters typically consist of a packing or media contained

in a vessel. The water to be treated is

sprayed over the top of the media and collected in a sump underneath the

media. The surface of the media or

packing provides the substrate for the growth of a biofilm. In large systems, air is forced into the

filter with a fan. However, small can

filters rely on natural convection and diffusion to move air throughout the

filter.

Trickling filters are rugged and easy to

operate. They have the ability to treat

a wide variety of nutrient levels.

Properly designed systems can handle solids very well. One of the big advantages

of a trickling filter is that the water can leave with more oxygen than it

entered. Because trickling filters have a large - air water interface, they

also act as strippers to remove CO2, H2S, N2 or other undesirable volatile

gases. The only major drawback to

trickling filters is the energy cost required to pump the water to the top of

the filter. A high narrow filter will

save space but take more pumping energy.

A wide low filter will use less energy but take up more space.

The first step in the design of a

trickling filter is to pick the right packing or media. Over the years many

different materials have been used for trickling filters but for the last 40

years, the best packing has been structured media. Structured media is composed of sheets of

rigid PVC that are corrugated and glued together to form blocks. For an in

depth review and analysis of packing materials, refer to the paper "A

Review of Biofiltration Packings".

One of the advantages of structured media

is its flexibility and ease of use.

Structured media can be used to build a small biofilter without a

vessel. Since the vessel is typically the major cost of a biofilter, a

biofilter with no vessel can be a real money saver. Structured media can be

stacked on a frame work or any flat surface.

It can be located over a culture tank or have its own water collecting

sump. No sides are required because the packing is self supporting. Of course, large systems are typically built

with walls and fans to move air through the media.

The most important requirement in the

design of any trickling filter is a good water distribution system at the top.

There are several ways to do this. A

pressure spray system with splash guards at the top is probably the

simplest. The only drawback is the

additional pressure drop required to operate the nozzle. The other system involves the construction of

a shallow water distribution pan with several gravity flow target nozzles in

the bottom of the pan. Here are some typical arrangements for a

"vessel-less" trickling filters.

Figure 1. Trickling filter with pressure nozzle

distribution system.

Fig. 2.

This is a trickling filter with gravity flow target nozzles in a shallow

water distribution pan.

Part of the art of designing a trickling

filter is to balance the competing requirements on the design.

1. In

order to keep the energy costs to a minimum, the pumping head for the filter

should be as low as possible. The

maximum plan area covered by the filter is determined by the minimum water

loading.

2. In

order to minimize the floor space used by the filter, the filter should be as

tall as possible. The practical

limitations are the height of the building, the head limits on the pump and the

structural and stability considerations of the vessel.

3. A

taller filter will have a longer flow path for the water. This means a more complete treatment of the

water with each pass.

4. Taller

filters will have higher specific water loadings. This means better flushing action, more

turbulent water films and higher ammonium removal rates.

Trickling filters for industrial applications

are sometimes 30 ft. tall. This is not

practical for aquaculture systems. In

general, trickling filters for aquaculture are between 4 and 10 ft. tall.

Submerged Bed Filters

Submerged

Bed Filters are familiar to anyone who has owned an aquarium. An under gravel

filter is a classic down flow submerged bed filter. Submerged bed filters have been used

extensively for small scale aquaculture and backyard water feature

systems. These filters can be operated

in up flow, down flow or cross (horizontal) flow. The classic (old) systems consisted of gravel

with an under drain system. An

improvement to these systems was the addition of air piping underneath. The air was used to 'bump' the filter to

dislodge solids that plugged the gravel and restore full flow. There are numerous problems with these types of filters. Their large size, low void fraction, tendency

to plug and extremely high weight make them expensive to build and

maintain. In general, these old gravel

based systems are not suitable for modern aquaculture.

Modern submerged bed filters are very

efficient, have low head loss and are very easy to build and maintain. The key difference is the type of media and

the water flow path. A modern submerged

filter uses structured media in a horizontal flow mode. This type of biofilter probably comes closer

to the ideal biofilter than any other type.

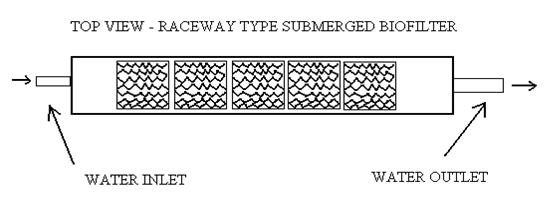

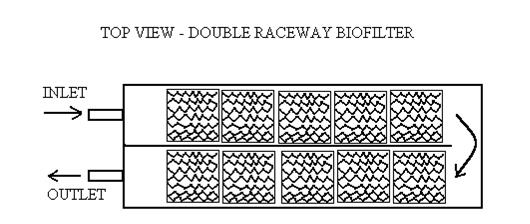

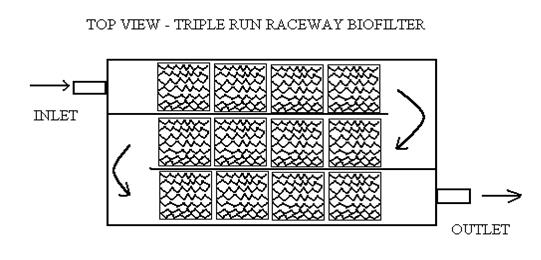

A typical installation would be configured

similar to a raceway. The filter media is

installed in a long trough. The length

of the flow path can vary based on the retention time required. By using a relatively high velocity, it is

possible to insure plug flow. This is a

big advantage over well mixed systems or systems with short retention

times. If it is not possible to remove

all of the BOD before the biofilter, one will establish different zones in the

filter. As nutrients are absorbed or

removed in the first sections of the filter, different types of organisms will

establish dominance in the zones where they enjoy optimum conditions. There are a variety of ways to configure a

raceway type system. Here are a few

examples

Figure 3.

Figure 4.

Figure 5.

Figure 6.

Submerged filters can operate with or

without aeration. If the flow path is

long and the nutrient loading is high, it is wise to have aeration in the

filter. One of the easier methods is the

traditional aeration system with large silica air stones.

Sometimes it is not possible to use a

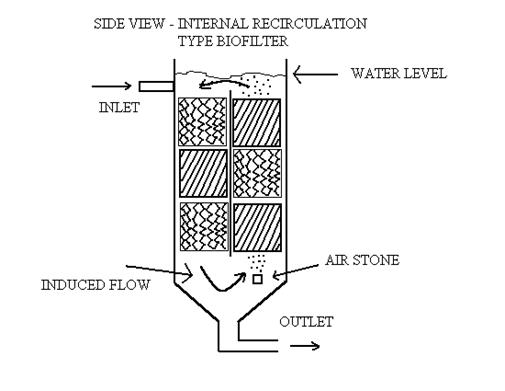

raceway type biofilter system. If

existing tanks must be used, it might be easier to build a system with internal

recirculation. The advantage of internal

recirculation is that it increases the velocity of water past the media and

adds oxygen to the water. Increasing the

velocity helps insure a more even distribution of water throughout the filter

media and reduces the possibility of dead zones that are not receiving

nutrients and oxygen. It also helps to

keep particles in suspension. Suspended

solids tend to settle out in areas of low water velocity. This is a problem because accumulations of

solids can become anaerobic and contribute to poor water quality. Here are a couple of examples of internal

recirculation systems. The cone bottom

tank is preferred over the flat bottom tank because any solids that settle out

will be removed immediately.

Figure 7

Figure 8.

There is always the possibility to install

the submerged biofilter media in the culture tank. This has the advantage of saving the cost a

separate vessel and associated piping.

The big disadvantage to this system is that it is difficult to remove

the suspended solids before the water enters the biofilter. Because there are too many different

configurations to draw them all, here is a brief description of a few of the

possibilities.

1. Air

lift the water into one end of a filter designed as a raceway and air lift it

back into the culture tank at the other end.

2. Pump

the water into a particulate filter such as a rotary drum and then flow through

the biofilter.

3. Locate

tubes or columns of packing throughout the culture tank and induce a flow

through them with air stones.

4. Locate

the filter media around the walls of the culture tank and induce a flow up

through the media with air stones.

The number of possible configurations is limited

only by one's imagination.

Submerged filters are excellent choices

for small systems because they are very versatile. They can be located in a separate tank or in

the culture tank. They can be horizontal flow, up flow or down flow. They can be aerated or not. The most important consideration for the design is the even

distribution of water to the packing. It

is very common for submerged filters to be designed as large, flat and thin

sections of packing with water direction being up flow or down flow. There is typically no provision for

distributing the water to all areas of the media. The length of the water path through the

media is very short and the resistance to flow is very low. This is a recipe for disaster. The water flow will short circuit though a

small section of the media

and the rest of the biofilter will become anaerobic.

Ideally the flow path through a submerged

filter should be as long as possible. A

long thin raceway is the best. This type

of biofilter is known as a long path, plug flow submerged filter.

Another possible

alternative is the use of aeration to induce a circulating flow

around a tank. The goal should always be

to provide sufficient velocity through the media to insure a fresh supply of

oxygen and nutrients to the bugs on the surface of the media.

NOTE:

This paper and other useful information for those interested in

aquaculture, aquariums or related topics can be found on the web at

http://www.biofilters.com

References

Greiner, A. D., Timmons, N. B., 1998.

Evaluation of the nitrification rates of microbead

and trickling filters in an intensive recirculating tilapia production

facility. Aquacultural Engineering pp 189 - 200

Kamstra,

A., Van der Heul, J.W., Nijhof,

M., 1998.

Performance and optimization of trickling filters on eel farms. Aquacultural Engineering pp 175-192

Saucier, B., Chen, S., Zhu, S.,

“Nitrification Potential and Oxygen Limitation in Biofilters” presented at the Third International

Conference on Recirulating Aquaculture July 2000.

Timmons, M.B., Losordo,

T. M., 1994. Aquaculture Water reuse Systems: Engineering Design and Management Elsevier

Science B.V.

Zhu and Chen “An experimental study on

nitrification biofilms performances using a series reactor system” Aquacultural

Engineering 1999 Vol 23, p. 245 – 259.

©1995-2003

by L. S. Enterprises. All rights

reserved. No part of this publication may be reproduced or transmitted in any

form or by any means electronic or mechanical, including photocopy, recording, or

any information storage and retrieval system, without permission in writing

from the publisher.

Published

by L. S. Enterprises

PO Box 13925

Gainesville,

FL 32604 USA

Author:

Matt Smith

Office 1-352-379-5626

Mobile

1-239-851-1175

Fax 1-866-706-1775

Email:

mattsmith@biofilters.com

rev.

8/15/2013